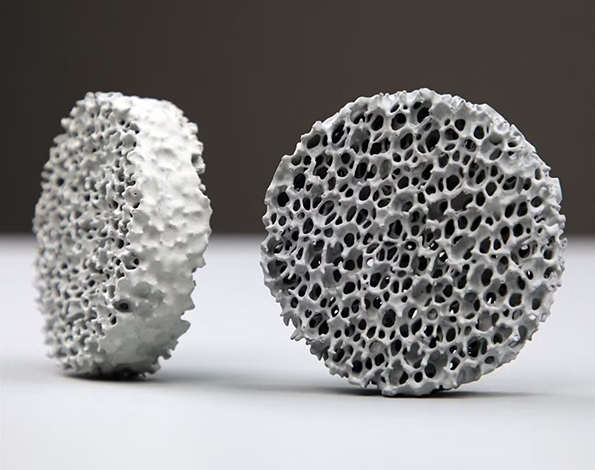

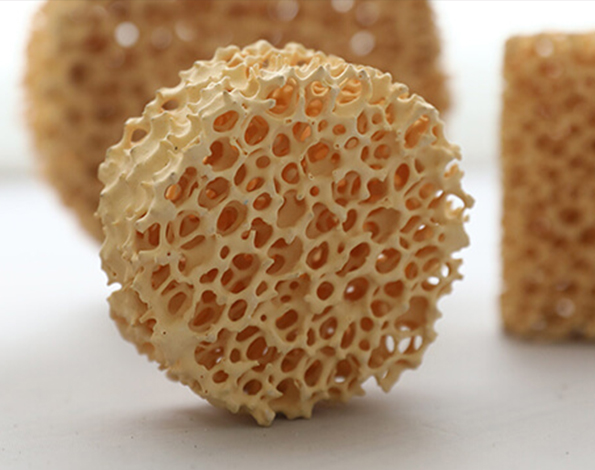

At GISBORNE Filter, we specialise in manufacturing high-performance ceramic foam filters designed to remove impurities from molten metal and improve casting quality. Our products are engineered with sponge-like porous structural foams that enable smooth metal flow, minimal turbulence, and a drastic reduction in casting defects. We currently manufacture two main filter types, each tailored for specific industrial needs and metal types:

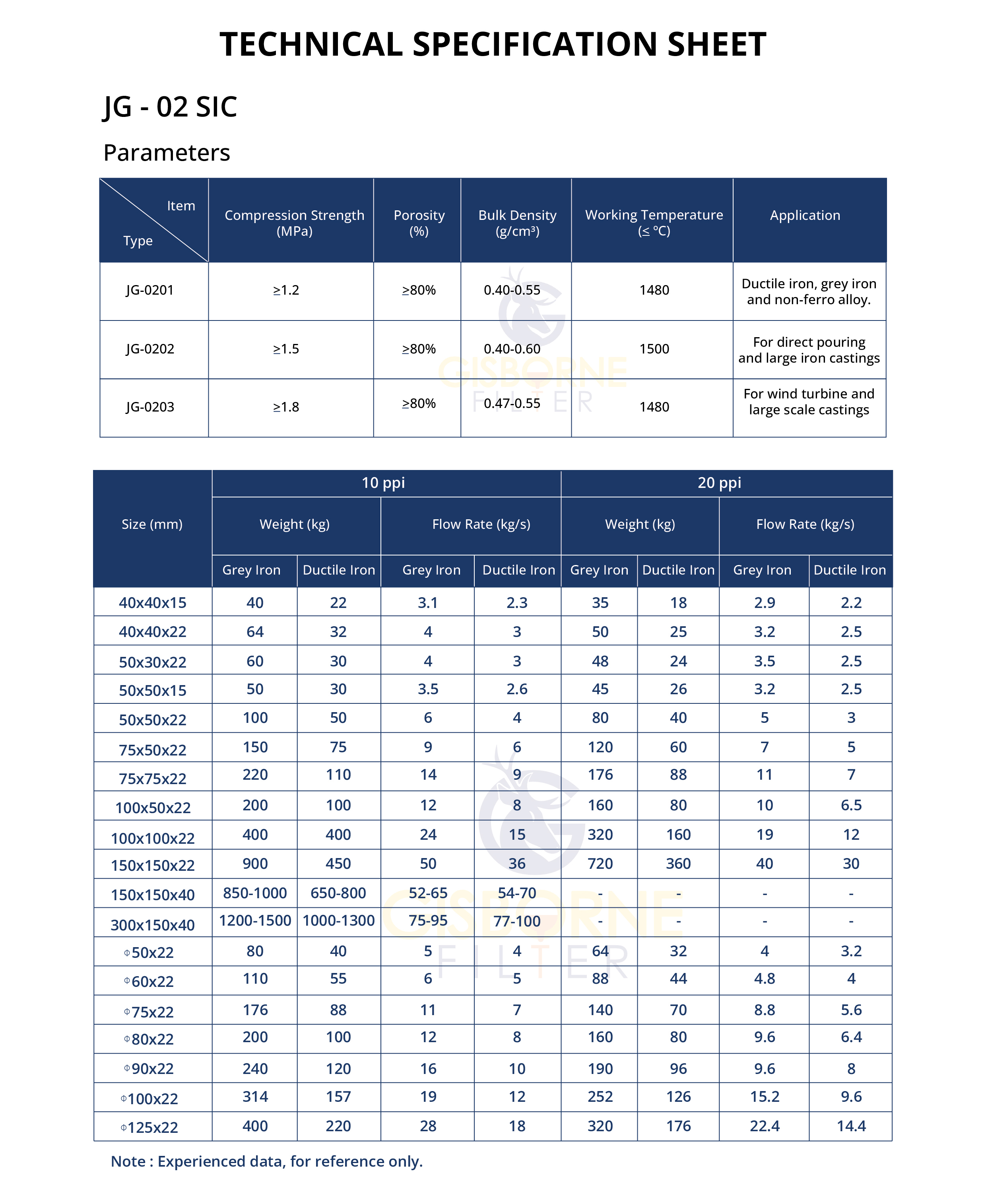

Our silicon carbide filters offer excellent mechanical strength and chemical stability under thermal stress. Ideal for high-volume foundries, they ensure longer service life, fewer rejections, and better metallurgical control.

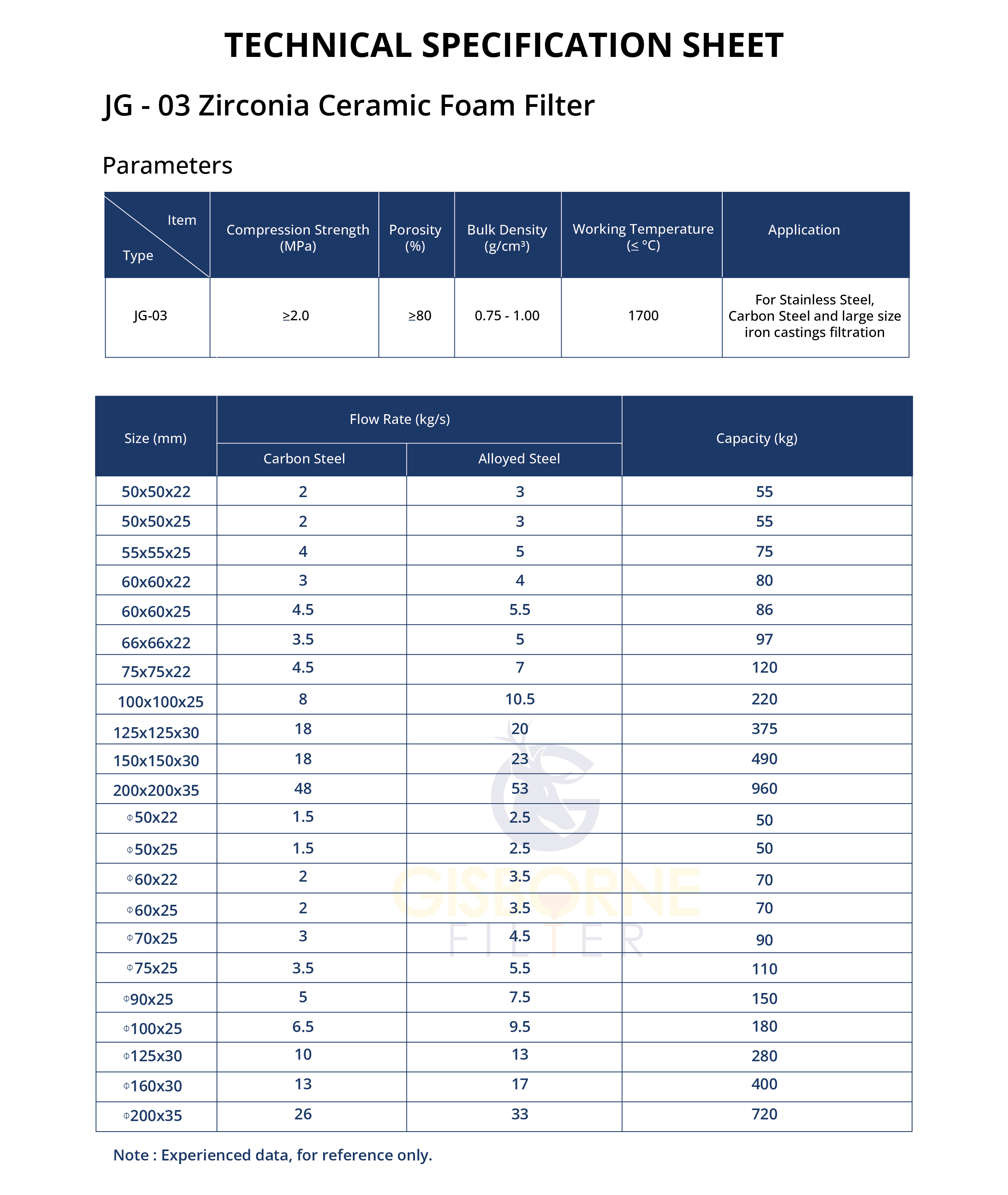

Zirconia filters are ideal for applications where cleanliness, consistency, and heat resistance are non-negotiable. Their engineered structure supports complex castings with tight tolerance requirements, reducing defects and improving surface integrity.

In addition to casting, our ceramic foam filters are used as porous combustion surfaces in gas burners, replacing open flames with radiant heat. These filters:

Need a specific size or porosity? We can tailor filter dimensions and grades to suit your foundry’s needs. Let us know your application, and we’ll recommend the right product.